WE PROVIDE HIGH-QUALITY FILTRATION TECHNOLOGY – BACKED BY EXPERIENCE AND EXPERTISE

Gib hier deine Überschrift ein

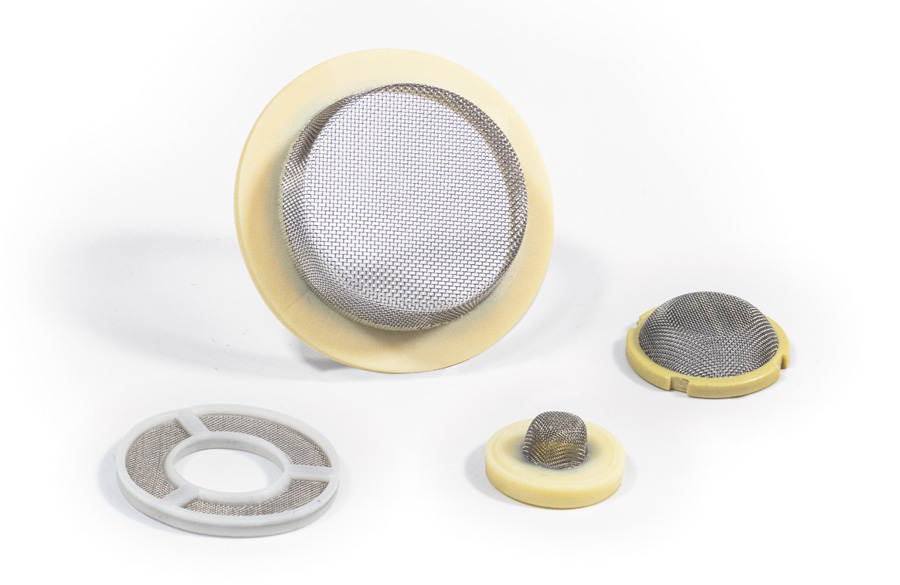

Filter Screens

in various material options – for maximum performance and reliability

Our filter screens and filter elements are manufactured using the injection molding process. In this process, high-grade plastic or metal meshes are precisely inserted into the mold and overmolded with plastic.

The result: A technically sophisticated, durable, and at the same time economical solution – ideal for serial production.

- Ultra-fine mesh with drinking water approval

- Custom configurations for hydraulic systems or high-temperature environments

- High resistance and reliability, even with challenging fluids

We have been developing and manufacturing complex assemblies together with our long-standing partners for over 30 years in medium-sized series. Our processes are well-established and quality-driven.

Our engineers support the development of optimally matched products

Because we know what you are talking about.

Thanks to our in-house expertise, you benefit from tangible advantages: short communication paths, fast coordination, and efficient solutions. Whether in planning, optimization, or during ongoing operations – our engineers understand your requirements and think ahead. This way, an idea becomes a technically refined solution – precise, cost-effective, and on schedule.

Filter Screens for Various Drinking Water Applications

For coarse and fine filters used in drinking water systems, we use stainless steel mesh and plastics with drinking water certification (such as KTW, WRAS, etc.), primarily:

POM, POM-GF30, PP, PP-GF30, TPE.

Filter Elements for Hydraulic Applications

Due to the required resistance to hydraulic oils, we primarily use: PES/PET mesh and Injection-molded housings made of PA6-GF25 or PA66-GF30

For higher temperatures or pressures, calendered stainless steel mesh is also employed.

Filling Sieves for Tanks and Containers

Depending on the application, we use: PA66, PE/PES, or stainless steel mesh. For the body material, typically PA6-GF25 or PA66-GF30

For special fluids like AdBlue, POM is used due to its higher resistance to urea.

Assemblies with Filter Screens

We also offer the integration of seals and/or additional components such as valves, flaps, or springs into our filter screens to create small subassemblies. For joining plastic components, integrated snap-fit connections are commonly used.

Some of Our References: